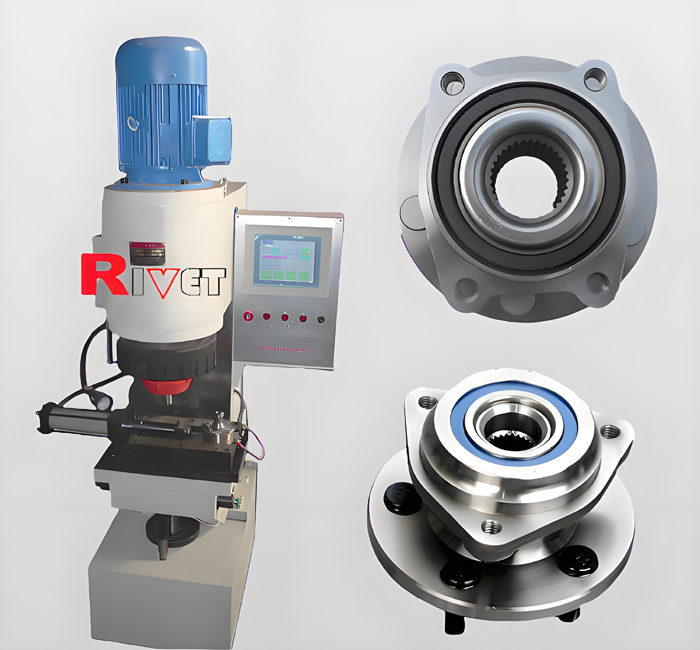

Focusing on the R&D and manufacturing of riveting machines

QYJ-K Series Automatic Hydraulic Fine Blanking Press

Classification:

Frame-type structure with high strength and stiffness.

Contact:

PRODUCTS

Details Introduction

QYJ-K Series Automatic Hydraulic Fine Blanking Press:

● Frame-type structure with high strength and stiffness.

● With octahedral guide rail, the main slider remains high precise motion under eccentric loads.

● After hardening surface treatment, the seal sliding parts possess ultra-high wear resistance.

● Two separated central pillars located at top and bottom are designed to reduce the load on the light-weighted molds.

● With mechanical and electrical detections,this double positioning system guarantees the high accuracy of repeatability.

● The automatic detection and feedback mechanism for mold plastic and foreign object effectively protects molds from being damaged.

● The hydraulic power packs are adopted with servo technology, which precisely controls the blanking forces and the associated stroke rates with limited vibration and noise.

● The finished workpieces are ejected automatically using air pressure.

● Using non-contact programming control system, the electrical elements are space saving,easy to operate and maintain, and have longer performance life.

● It is optional to add coil straightening machine with auto-feed or self-lubricating system.

● The automatic workpiece delivery, collection, segregation and inspection system could form the automatic fine blanking production line.

Standard setup:

● Auto-feed machine.

Controlled by servo system, the auto-feed machine adjusts all the parameters based on the workpieces’ material and thickness.

● Self-oiling mechanism.

The upper and lower surfaces of the raw material are evenly covered by lubricant through spinning roller so that the finishing quality could be guaranteed and mold’s performance life could be extended.

● Waste shearing machine.

Based on operation requirements, the shearing rate could be adjusted to easily collect waste.

● Mold support.

The foldable mold support guarantees the operator’s safety and is easy for mold’s assembly and disassembly.

Optonal setup:

●Coil Straightening Machine

Different specifications are available.

●Hydraulic Mold Fastening Device

To improve retooling efficiency.

●Oil Mist Separator

To clean the working environment by absorbing dust and oil mist.

●Photoelectric Sensor

To protect the operator under misuse failure.

●Conveyor Belt

To deliver the finished product to the specified location.

| QYJ-K Series Technical Specifications | |||||||

| Specification | Unit | QYJ-160Z | QYJ-250Z | QYJ-320Z | QYJ-400Z | QYJ-500 Z | QYJ-650Z |

| Max Force | KN | 3200 | 4000 | 5000 | 6500 | 8000 | 10000 |

| Max Blank Holder Force | KN | 1600 | 2000 | 2500 | 3250 | 4000 | 5000 |

| Max Return Force | KN | 720 | 900 | 1120 | 1400 | 1800 | 2250 |

| Max Ejection Force | KN | 360 | 450 | 560 | 700 | 900 | 1123 |

| Max Blank Holder Travel | mm | 30 | 40 | 40 | 50 | 50 | 60 |

| Max Return Travel | mm | 30 | 40 | 40 | 50 | 50 | 60 |

| Blanking Speed | mm/s | 5-50 | 5-45 | 5-45 | 5-40 | 5-40 | 5-30 |

| Idle Speed | mm/s | 220 | 200 | 200 | 200 | 150 | 150 |

| Return Speed | mm/s | 220 | 200 | 200 | 200 | 150 | 150 |

| Adjustable Mold Range | mm | 300-400 | 300-420 | 300-420 | 320-450 | 320-450 | 400-550 |

| Max Workspace | mm | 500 | 520 | 520 | 580 | 580 | 700 |

| Workbench Dimension | mm | 650*750 | 750*850 | 750*850 | 850*950 | 850*950 | 950*1050 |

| Max NO. of Stroke | S.P.M | 40 | 40 | 40 | 40 | 35 | 35 |

| Max Pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 |

| Max Power | KW | 55 | 65 | 65 | 75 | 90 | 130 |

Keyword:

QYJ-K Series Automatic Hydraulic Fine Blanking Press

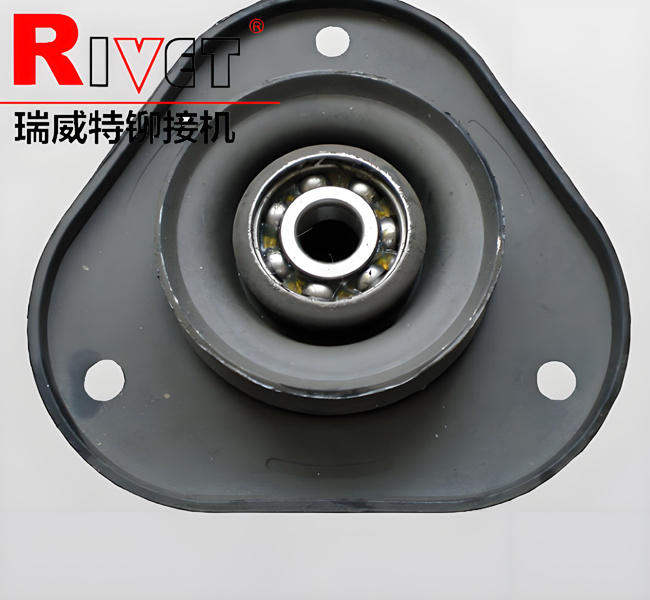

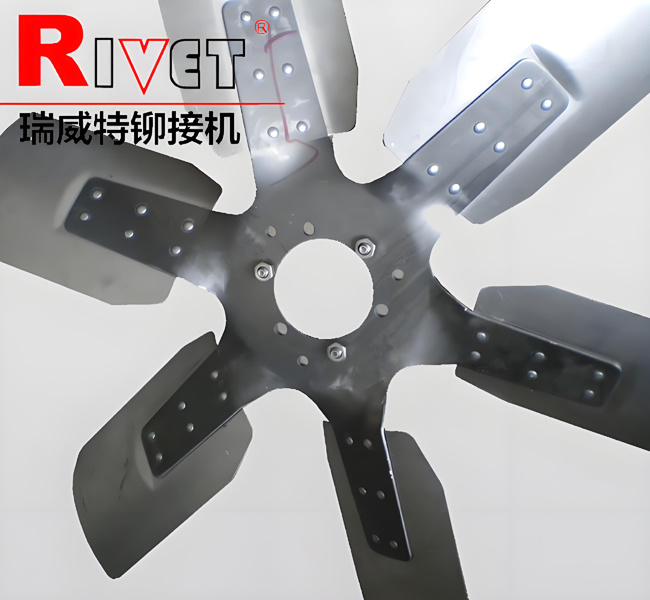

APPLICATION CASES

RELATED PRODUCTS

Message consultation

Every message will be taken seriously and promptly responded to by us.