Focusing on the R&D and manufacturing of riveting machines

Vibrating plate riveting machine,Automatic feeding riveting machine,Cutch riveter

Classification:

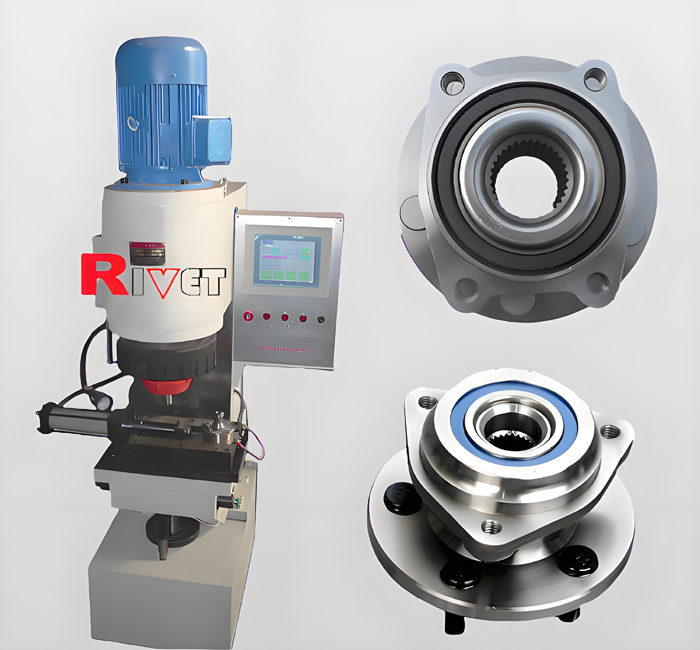

The machine used for process automotive clutch plates. Operator assembles workpiece and put it into positioning guide pin and steping foot switch, the rivet is automatically fed into hole to perform riveting, the all action is controlled by PLC.The rivets move by pneumatics, and other actions are performed by vibrating plates and pneumatic actuators.

Contact:

PRODUCTS

Details Introduction

Processing scope and requirements:

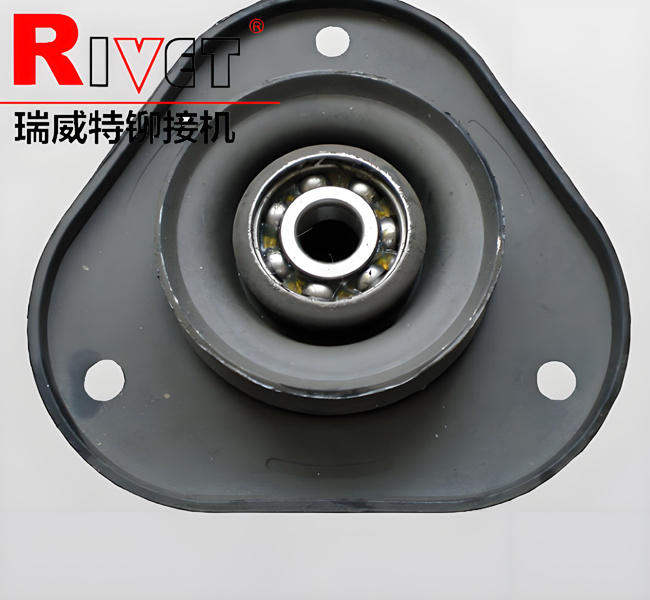

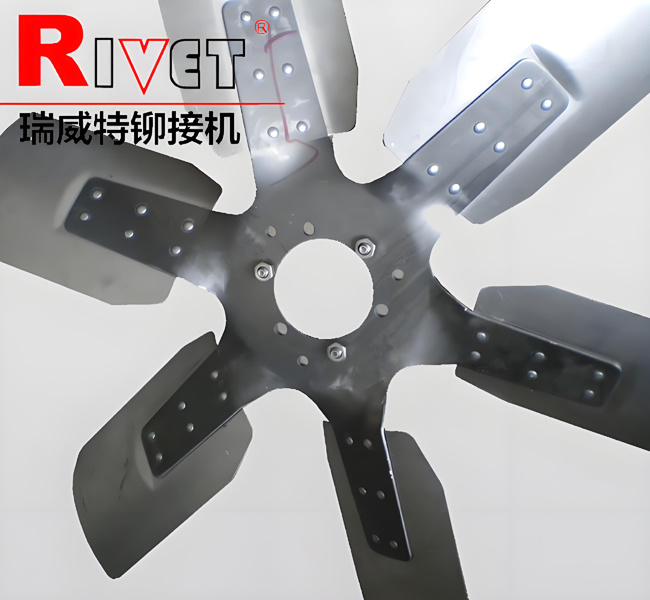

● For riveting join clutch corrugated plate and fricationdisc.

● Driven plate assembly diameter range is Ф228mm~Ф430mm.

● Driven friction disc and corrugated plate diameter is Φ196mm~Ф370mm.

● Corrugated plate rivet hole dimater is 5.2mm(0-0.15mm):friction disc rivet hole diameter is 5.2mm (0-0.2):

● Both sides of rivet total 18 Nos and processing time less than 55 Seconds.

● Evenly and without skewing after riveted, flanging area no clearance check by 0.05mm feeler gauge.

● Riveted torque meter detacts 10 pieces clutch assembly (total 180 rivets) and torque in the range of 1-1.75N.m.

Equipment requirements:

● The device operation interface is English.

● Upper tool center guide bar reposition by spring.

● Lower riveting tool guide bar stretching by pneumatic, and guide bar pressure adjusting by pneumatic valve.

● Lower riveting tool guide bar's pressure large than upper tool spring force.

● Riveting tool Service life more than 50000 times.

● When the equipment fails, it can stop automatically and there is sound and light alarm.

● The master cylinder uses a precision pressure regulator to connect the cylinder pressure. In the air-off state, the cylinder head can remain in place and does not fall off.

● Automatic grease filling is added to the main lubrication area of the equipment. If the manual lubrication that must be marked.

● The device power switch is locked and can be locked when the power is turned off.

● Emergency stop button with self-locking function, mushroom head is red, start button is green.

Equipment operation process:

● The actuator is in place when machine is turned on, the vibrating plate to detect the rivet signal to determines whether switch on or not.

● Manual put clutch to position and sensor detact placed or not to prevent misues,and then step on the foot switch.

● Pneumatic sylinder down and put rivet on hole ,riveting ,and rivet slide way to separate rivet one time.

● Riveting cylinder rises to original position and fixed rivet channel to separate one time.

● Return to execute the next operatio.

Keyword:

Vibrating plate riveting machine,Automatic feeding riveting machine,Cutch riveter

APPLICATION CASES

RELATED PRODUCTS

Message consultation

Every message will be taken seriously and promptly responded to by us.